Image for Illustration purposes only. Actual product may vary

Red Lion Controls PSC11004 PSCN4XNI AL1&2ANL485

MODEL PSC11004

Contact supplier for technical support on: 877-432-9908

$656.00 Each

Prices are subject to change

FREE SHIPPING ON ORDERS OVER $1

Select Quantity

Free Gift with this product

Free Gift with this product

Typically Ships in: 1 day

Returnable: See conditions

Still Deciding?

Add this item to your saved items and easily come back later.

Description

The PSC is a setpoint controller suitable for time vs. process control applications. The PSC Controller accepts either a 0-10 VDC or a 4-20 mA DC input signal, precisely scales the process signal, according to programmable scaling points, and provides an accurate output control signal (time proportional or linear) to maintain a process at the desired control point. A comprehensive set of easy to use steps allows the controller to satisfy various applications. The user input can be programmed to perform a variety of controller functions.

Dual 4-digit displays allow viewing of the measured process value and setpoint or the process and profile status simultaneously. Front panel indicators inform the operator of controller status and output states. Replaceable output modules (Relay, Logic/SSR drive or Triac) can be fitted to the main control output, alarm output(s) or timed event output(s), and secondary output.

The PSC has been designed to simplify the set-up and operation of a controlled setpoint profile program. The setpoint program is easily entered and controlled through the front panel. Full display capabilities keep the operator informed of the process value, profile status, output states, and setpoint value.

The controller can operate in the standard PID control mode for both Output 1 and Output 2 with on-demand auto-tune which establishes the PID gain set. The PID gain set can be fine tuned by the operator at any time or may be locked from further modification. The unit can be transferred to the manual control mode providing the operator with direct control of the output.

The PSC features four programs or profile recipes, each with up to eight ramp/soak segments, which can be easily stored and executed at any time. Longer profiles can be achieved by linking one or more profiles together, creating a single profile of up to 32 ramp/soak segments. Process profile conformity is assured during either soak (hold) phases or both ramp and hold phases by an adjustable error band parameter. The program repeat function cycles the profile either continuously or a set number of times. Power-on options automatically re-start, stop, or resume a running profile. The profile can be controlled via the front panel buttons, the user input, or the optional serial communications port.

Four control points, each having a setpoint and PID parameter set, are available for instant front panel implementation during batch changeover, or other process conditions. A control point may have its PID gain set values disabled when implementing the control point.

The RS485 multidrop serial communications interface provides the capability of two-way communication between a PSC unit and other compatible equipment such as a printer, a programmable controller, or a host computer. In multipoint applications the address number of each unit on the line can be programmed from 0 to 99. Up to thirty-two units can be installed on a single pair of wires. The Setpoint value, % Output Power, Setpoint Ramp Rate, etc. can be interrogated or changed by sending the proper command code via serial communications. Alarm output(s) may also be reset via the serial communications interface option.

Optional alarm output(s) may be configured to operate as a timed event output or as a standard alarm output. As an alarm output it may be configured to activate according to a variety of actions (Absolute HI or LO, Deviation HI or LO, or Band IN or OUT) with adjustable hysteresis. Also, a standby feature suppresses the output(s) on power-up until the process stabilizes outside the alarm region. Timed event output(s) allow the controller to activate other equipment while a programmed profile is running. Each profile can define up to 16 event states (phases), for each output(s).

The linear 4 to 20 mA or 0 to 10 VDC output signal is available to interface with final actuators, chart recorders, indicators, or other controllers. The output signal can be digitally scaled and selected to transmit one of the following:

A NEMA 4X/IP65 rated bezel is available for washdown and/or dirty environments, when properly installed. Modern surface-mount technology, extensive testing, plus high immunity to noise interference, makes the controller extremely reliable in industrial environments.

Note: Output Modules are NOT supplied with the controller. When specifying the controller, be sure to purchase the appropriate output module for the Main Control Output and if necessary, the alarm output(s), the secondary output, and valve positioner outputs.

The Logic/SSR Drive Module is a switched DC source, intended to drive the DC input of an SSR power unit. It should never be connected to line voltage.

All modules are packaged separately and must be installed by the user.

Specifications

- 97 mm x 50 mm

- Dual 4 Digit, 0. 4" (10 mm) LED, 0. 3" (7. 6 mm) LED

- 0 to 10 VDC or 0 (4) to 20 mA Input

- Ramp/Soak

- Event Outputs

- Multi-setpoint

- Dual Alarms

- RS-485 Communication

- Linear 4 to 20 mA Outputs

Accessories

| CCA3PC00 | CABLE 10' 3Pin Connector Extension |

|---|---|

| CCA3PC25 | CABLE 25 Feet 3Pin Connector Extension |

| CCA3PC50 | CABLE 50 Feet 3Pin Connector Extension |

| BMK40000 | BMK4 Base Mount Kit for Apollo, Gemini, PAX, TCU, PCU, TSC, PSC and PXU |

| OMD00000 | OMD Relay Module for PCU, PSC, TCU and TSC |

| OMD00001 | OMD Triac Module |

| OMD00003 | OMD Logic/SSR Drive Module |

SKU: 286716

Arived with the readout actully working

This one worked. Second one I ordered, one from another supplier. First one was dead. Battery is supposed to last for 5 years, it's an "always on" setup. Mine first one did last the 5 years. I use this on my milling machine powered by a VFD.

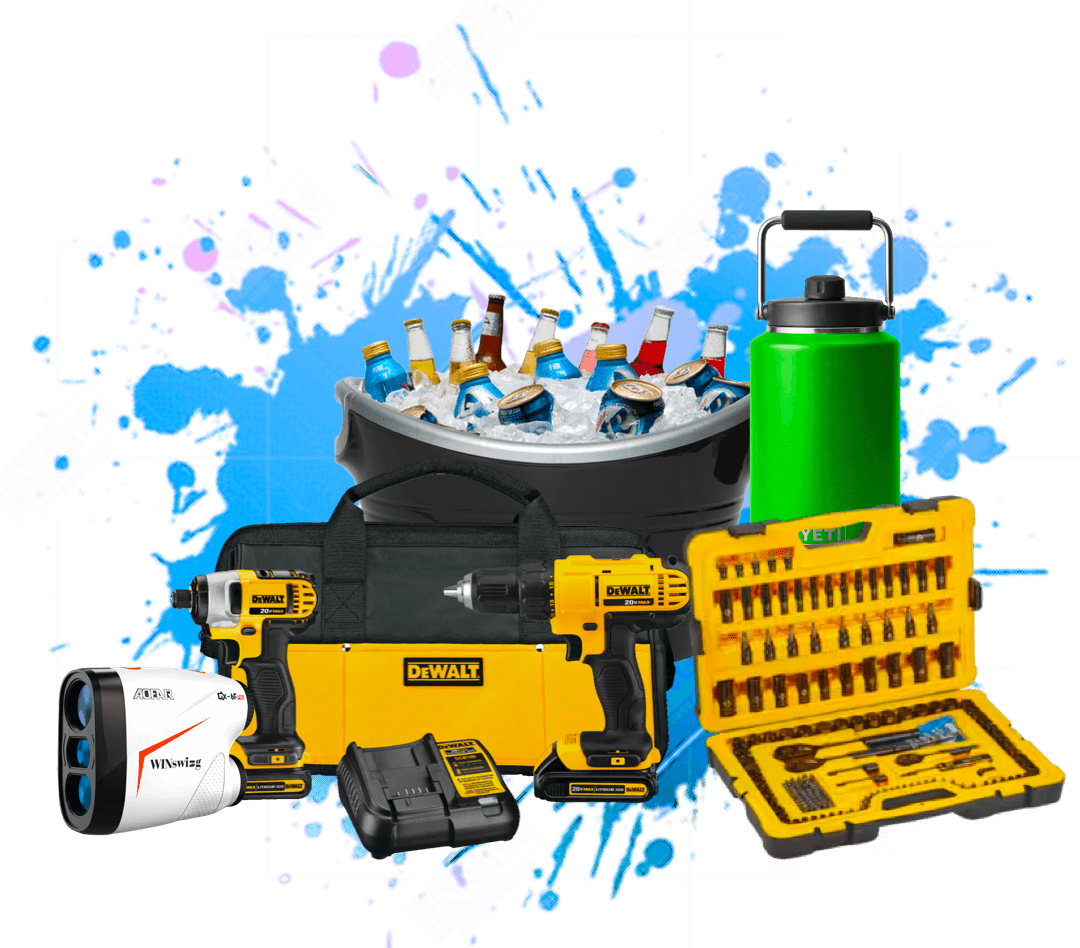

Read moreWhen you get to checkout, you’ll be able to select a free gift! Depending on the cart value, you’ll be shown relevant gifts your order qualifies for.

$500

MRO Hat

MRO Golf Balls

MRO Hi-Vis Vests

MRO Mug

$750

32oz Water Bottle

Throw Blanket

30 piece Hex Set

Telescopic Pick Up

$1,250

Golf Cooler

11-in-1 Screw Driver Set

Gorilla Grip Knee Pad

John Deere Oilskin Hat

$2,500

Igloo 1/2 Gallon Jug

Rechargable Headlamp

Larix Trucker Hat

$5,000

Igloo 10 Gallon Cooler

Igloo Party Bucket Cooler

Klein Tools Speaker

Klein Tools 8-in-1

$7,500

GX-6F Pro Golf Range Finder

Bushnell Outdoorsman Speaker

Jaeger 24px Ratcheting Wrench Set

Aspen Beverage Bucket