Image for Illustration purposes only. Actual product may vary

MRC CTW115ZM Pillow Block Wash Down

MODEL CTW115ZM

$288.16 Each

Prices are subject to change

FREE SHIPPING ON ORDERS OVER $1

Select Quantity

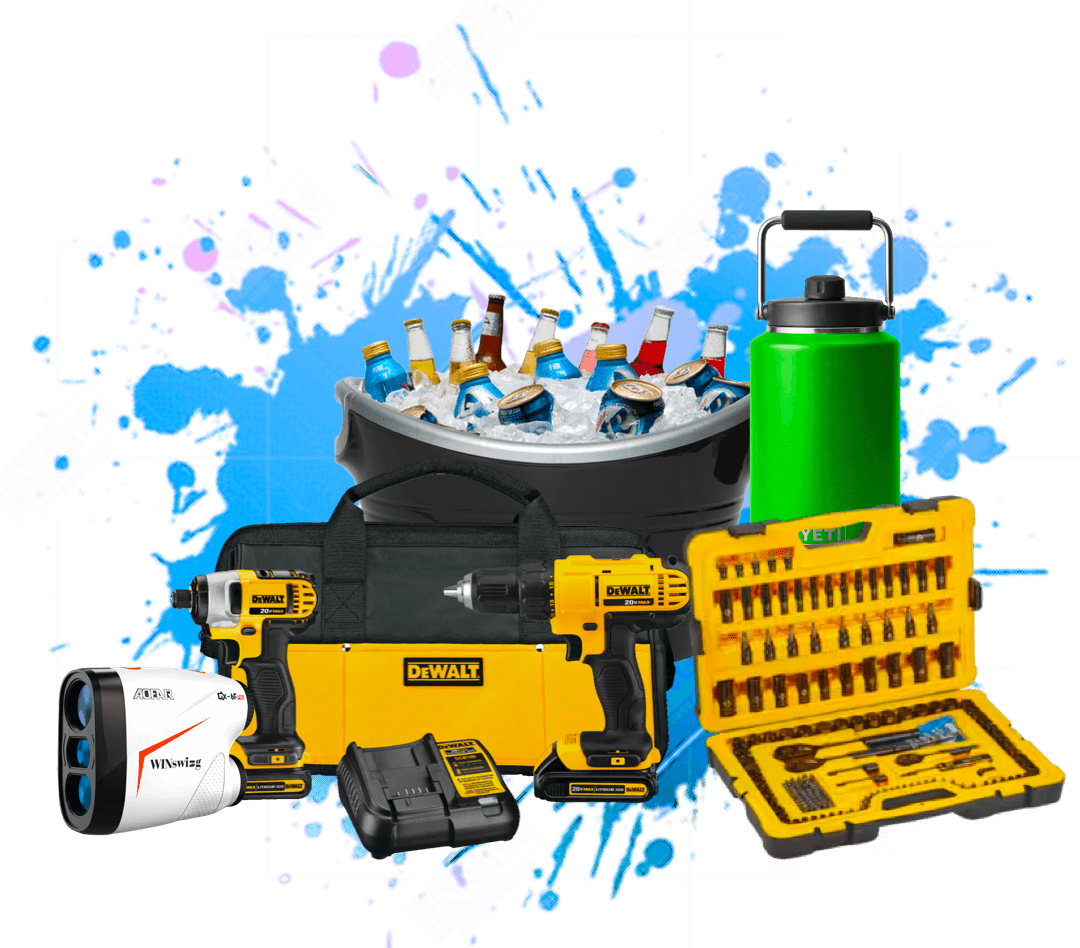

Orders over $500 qualify for a Free Gift

Orders over $500 qualify for a Free Gift

Typically Ships in: 1 day

Returnable: See conditions

Still Deciding?

Add this item to your saved items and easily come back later.

Locking

Setscrew Locking Inner Ring

Item Details

| Manufacturer: | MRC Bearing Service |

|---|---|

| Weight: | 2. 65 lbs. |

| Product Name: | Marathon Series Wide Slot Take-Up Unit |

| Description: | 1 15/16" Shaft, 11/16" Slot Width, 4" Between Frames, Composite, Contact Seals, Non-Relubricatable, Non-Expansion, ZMaRC Coated Insert |

Specifications

| Inch/Metric | Inch |

|---|---|

| Shaft Dia. [Min] | |

| Shaft Dia. [Max] | |

| Shaft Dia. | 1 15/16 in |

| Slot Width [Min] | |

| Slot Width | 11/16 in |

| Between Frame Width | 4 in |

| Housing Material | Composite |

| Locking Device | Setscrew Locking Inner Ring |

| Lubrication | Non-Relubricatable |

| Overall Height [Min] | |

| Overall Height [Max] | |

| Overall Height | 4 3/4 in |

| Seal Type | Contact Seals |

| Type | Ball Bearing |

| Bearing Design | Non-Expansion |

| Insert Type | ZMaRC Coated Insert |

| Bearing Insert | RRZ1115BRR |

| Center of Bearing to Back of Inner Ring | |

| Center of Bearing to Front of Inner Ring | |

| Center of Shaft to End Opposite Shank | |

| Collar No. | |

| Dynamic Load Rating | 7890 lbf |

| End Type | |

| Housing No. | |

| Housing Width | 1 15/16 in |

| Length Through Bore | |

| Overall Length [Min] | |

| Overall Length [Max] | |

| Overall Length | 5 13/16 in |

| Overall Width | |

| Screw Diameter | 1 1/16 in |

| Screw Hole Diameter | |

| Shank Diameter | |

| Shank End to Center of Shaft | 3 9/16 in |

| Shank Height | |

| Shank Slot Height | |

| Shank Slot Length | |

| Shank Slot to Center of Shaft | |

| Shank Slot to End | |

| Shank Slot Width | |

| Shank Thread Size | |

| Size Code | |

| Slot Length | |

| Special Features | |

| Static Load Rating [Max] | 5220 lbf |

| Take-Up Frame No. | |

| Take-Up Types | Wide Slot |

| Temperature Range [Min] | |

| Temperature Range [Max] | |

| Threaded End Width | |

Product Information

| Description | The composite housing can be easily washed clean of contaminants encountered in food and beverage processing. Designed to provide corrosion resistance, food and beverage compatibility, and long service life. |

|---|---|

| Applications |

|

| Features |

|

| Benefits |

|

| Compliances |

|

SKU: 1133536

Great bearings, great price!

I am rebuilding an old Delta/Rockwell drill press and was having trouble finding the correct replacement bearings at a reasonable price from my usual go-to online dealers; from those that even had them available. Shipping times where reasonable. Competitively priced at time of purchase. Stock status was available, had to use contact link to make sure they were available to ship. Would be very nice if real-time in-stock status could be available while hunting down need parts, but in the long run it's not that big of deal. The stock status email back following the inquire was quick with a quoted price and purchase link.

Read moreSKU: 1133538

Motor bearings

Of all the bearings I have purchased in the last 45 years, these look to be top quality.

Read moreWhen you get to checkout, you’ll be able to select a free gift! Depending on the cart value, you’ll be shown relevant gifts your order qualifies for.

$500

MRO Hat

MRO Golf Balls

MRO Hi-Vis Vests

MRO Mug

$750

32oz Water Bottle

Throw Blanket

30 piece Hex Set

Telescopic Pick Up

$1,250

Golf Cooler

11-in-1 Screw Driver Set

Gorilla Grip Knee Pad

John Deere Oilskin Hat

$2,500

Igloo 1/2 Gallon Jug

Rechargable Headlamp

Larix Trucker Hat

$5,000

Igloo 10 Gallon Cooler

Igloo Party Bucket Cooler

Klein Tools Speaker

Klein Tools 8-in-1

$7,500

GX-6F Pro Golf Range Finder

Bushnell Outdoorsman Speaker

Jaeger 24px Ratcheting Wrench Set

Aspen Beverage Bucket