Image for Illustration purposes only. Actual product may vary

$149.19 Each

Prices are subject to change

FREE SHIPPING ON ORDERS OVER $1

Select Quantity

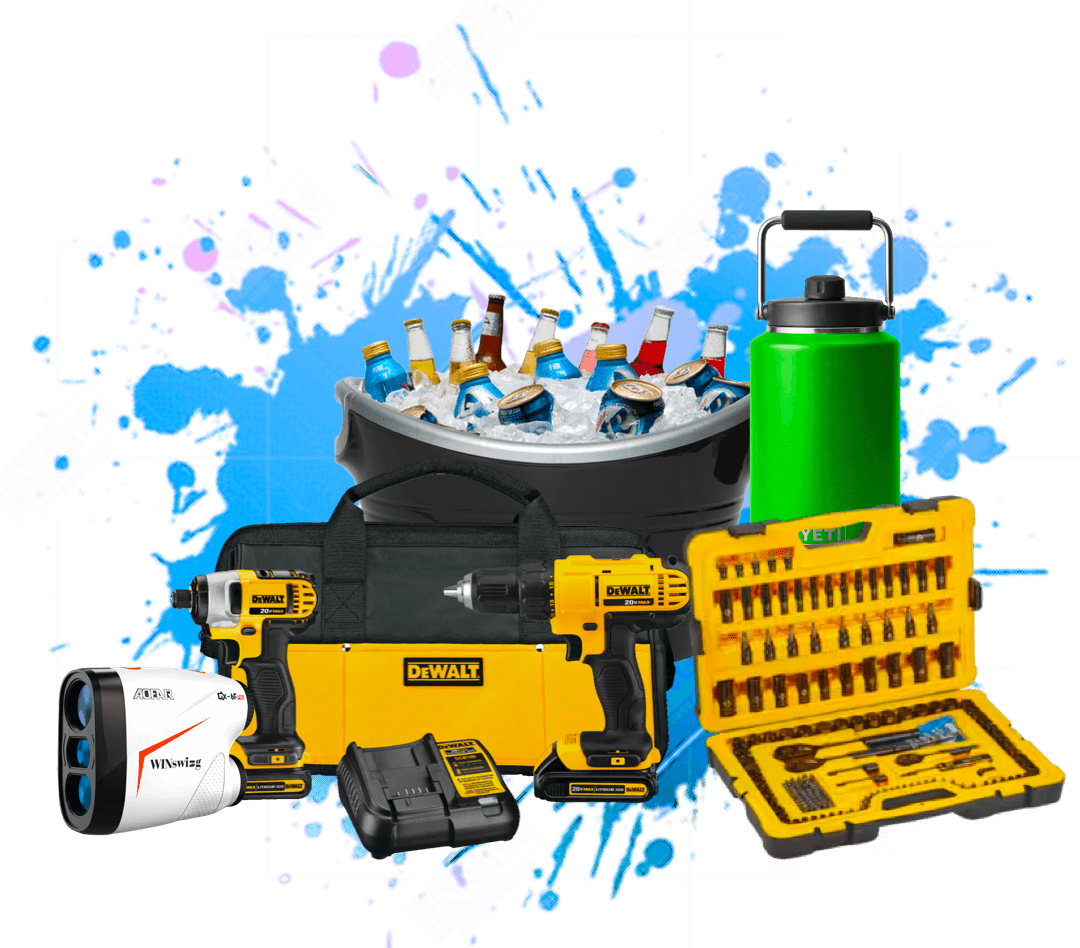

Orders over $500 qualify for a Free Gift

Orders over $500 qualify for a Free Gift

Typically Ships in: 1 day

Returnable: See conditions

Still Deciding?

Add this item to your saved items and easily come back later.

Horsepower rating at 3450 RPM

204

Outside diameter

7.0625

Stiffness (in lbs rad)

10980

Horsepower rating at 690 RPM

41

Max compatible bore size

3.375

Max speed

3600

Sleeve width

3.4375

KW rating at 100 RPM

4.4

Torsional stiffness

10980

Max angular gap misalignment

0.128 in

Power rating at 100 RPM

4.4 kW

Insert design

Two-Piece with Retaining Ring

Dimension (in) (D)

7 1/16

Temperature rating

-0°F to 200°F

Material type

Neoprene

Horsepower rating at 1800 RPM

17

Horsepower Rating at 100 RPM

5.9

Min compatible bore size

0.4375

Dimension (in) (W)

3-7/16

Operating temperature

-18°C to +93°C

KW rating at 970 RPM

43

Horsepower rating at 3600 RPM

213

Max parallel misalignment

10

Component WR2 (lbs ft2)

0.1862

Horsepower rating at 1750 RPM

16

Horsepower rating at 1200 RPM

71

Component WR²

0.1862

Screw type

Sleeve, Two-Piece with Ring

Max RPM

3600

Torque rate

422

Temperature rating (F)

+200ºF to -0ºF

Stiffness

1241

Horsepower rating at 50 RPM

3

Maximum angular gap misalignment (in)

0.128

Horsepower rating at 300 RPM

18

KW rating at 1450 RPM

64

Max angular misalignment

1°

Coupling size

10

Horsepower rating at 870 RPM

52

Torque

3,735 in-lb

KW rating at 3000 RPM

133

Horsepower rating at 1150 RPM

68

Torque rating (in lbs)

2875

Maximum parallel misalignment (in)

0.025

SKU: 336840

Muy buen servicio y rapidez en la entrega

Primera vez q compro con esta compañía, recomiendo ampliamente comprar con ellos y claro q volveria a comprar otra vez muy buen servicio y entrega rapida

Read moreWhen you get to checkout, you’ll be able to select a free gift! Depending on the cart value, you’ll be shown relevant gifts your order qualifies for.

$500

MRO Hat

MRO Golf Balls

MRO Hi-Vis Vests

MRO Mug

$750

32oz Water Bottle

Throw Blanket

30 piece Hex Set

Telescopic Pick Up

$1,250

Golf Cooler

11-in-1 Screw Driver Set

Gorilla Grip Knee Pad

John Deere Oilskin Hat

$2,500

Igloo 1/2 Gallon Jug

Rechargable Headlamp

Larix Trucker Hat

$5,000

Igloo 10 Gallon Cooler

Igloo Party Bucket Cooler

Klein Tools Speaker

Klein Tools 8-in-1

$7,500

GX-6F Pro Golf Range Finder

Bushnell Outdoorsman Speaker

Jaeger 24px Ratcheting Wrench Set

Aspen Beverage Bucket

Disclaimer: The return policy information shown below is merely a copy of the text as stated in TB Wood's Terms and Conditions.

File: http://documents.mrosupply.com/file_uploads/TB%20Woods%20Terms%20and%20Conditions.html

3. Claims for refunds or replacements must be made to the factory. Products may be returned only after written approval and a returned goods authorization number has been received from Customer Service or Application Engineering. Return shipments must be prepaid (Refer to Returned Goods Policy). Final decision about refund or replacement rests solely with TB Wood's Incorporated.

--

Disclaimer: The return policy featured below is for distributors only. Also, it is merely a copy of the text from TB Wood's Distributor Policy and Procedures.

File: http://documents.mrosupply.com/file_uploads/TB%20Woods%20Distributor%20Policies%20and%20Procedures.pdf

Returned Goods

The policy for returning products for defects in workmanship or materials is covered under the “Product Reliability” section.

Distributors and, occasionally, OEMs may want to return products that are overstocked or slow moving. Prior approval and a returned goods authorization number must be obtained from Customer Service or Application Engineering. This number must be referenced on the returned goods shipment. It allows us to identify the contents of the shipment, the Distributor who originated it and the reason for return. Freight must be prepaid.

Products returned for reasons other than factory authorized stock adjustments must have approval from Customer Service or Application Engineering and a returned goods authorization number. They must be sent by prepaid freight and will be subject to a 15% restocking charge. There will be additional charges as necessary for re-boxing and refurbishing. Returned goods must have been manufactured and/or sold by TB Wood’s Incorporated and must be in salable condition. They will be inspected at the factory and if reconditioning is necessary it will be charged to the Distributor. We reserve the right to reject unsalable products.

No products will be accepted for return or exchange if they are obsolete.