Image for Illustration purposes only. Actual product may vary

17Q10H14WP Cast Iron Worm Gearbox

- Ratio: 10:1

- Center Distance: 1.7"

- Input: 140TC Flange

- Output Bore/Shaft Diameter: 1"

- Output: Hollow Bore

- Paint/Coating: White

- Housing Material: Cast Iron

- Housing Material: Cast Iron

- Input Horse Power: 1.67

- Output Horse Power: 1.48

MODEL 17Q10H14WP

Contact supplier for technical support on: 864-284-5700

$956.33 Each

Prices are subject to change

FREE SHIPPING ON ORDERS OVER $1

Select Quantity

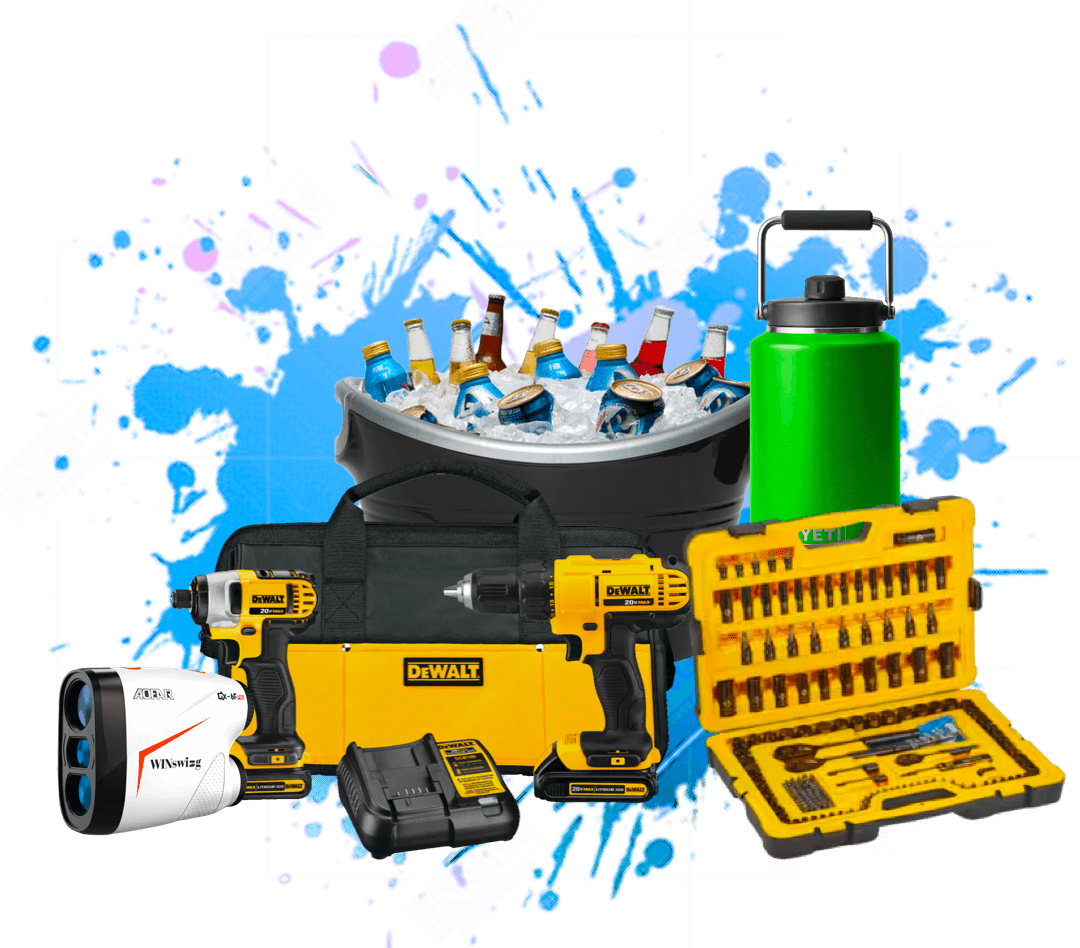

Free Gift with this product

Free Gift with this product

Typically Ships in: 1 day

Returnable:No

Still Deciding?

Add this item to your saved items and easily come back later.

Input style

Quill

Finish

White epoxy

Input HP

1.67

Bore length

5.4100 in, 137.414 mm

Input flange

140TC

Center distance (in)

1.7 in, Center distance (in):1.7500 in, 44.45 mm

Housing material

Cast iron

Paint/coating

White

Output bore/shaft diameter

1 in

Input

140TC flange

Output

Hollow bore

Output horse power

1.48

Ratio

10 to 1

Rated torque output

534 in/lb, 534.0 in/lb

Horsepower rating output

1.4800 hp, 1.104 kW

Paint type

White epoxy

Thermal horsepower rating

2.7600 hp, 2.058 kW

Nominal ratio

10

Base to output center height

1.9900 in, 50.546 mm

Mounting bolt pattern length

4.1900 in, 106.426 mm

Motor compatibility

NEMA motor, 140TC frame

Mounting bolt pattern width

2.7500 in, 69.85 mm

Output style

Hollow

Output shaft center to input motor mounting face distance

4.9000 in, 124.46 mm

Case size

17

Seal type

Single-lip contact

Lubrication type

PAG, standard temperature

Horsepower rating input

1.6700 hp, 1.245 kW

Bore dia output

1.0000 in, 25.4 mm

Overhung load

1190 lbf, 5293.384 N

Suitable for washdown

No

Tigear® stands for “Tough Industrial Gear”

The Tigear-2 reducer is built with the uncompromising Dodge® design standard to provide long life in demanding industrial applications. After decades of proven field experience, side-by-side testing in our advanced lab demonstrated its best-in-class durability over the competition.

The rigorous testing compared three brand-new gearboxes from each of the three manufacturers. Each gearbox was a two-inch center distance, a 15:1 ratio, and used the manufacturer’s highest quality oil offered (the standard for Dodge is the highest quality offering). All units were tested at an output torque of 1,580 lb-in, which is equivalent to the following ratings for each gearbox: 200 percent for Tigear-2, 197 percent for Competitor B, and 179 percent for Competitor C.

Testing was performed for 500 hours or until gearbox failure, whichever came first. Once testing was complete, each unit was disassembled for evaluation with inspection of individual components.

Features and benefits

- 12 case sizes

- 1.33” to 4.75” center distances

- 5:1 to 60:1 reductions

- Quill input

- Separate input

- 3-piece coupled input

- Solid output

- Hollow output

On average, Tigear-2 delivers more torque than competitive, same-sized models. This permits downsizing and helps reduce total cost of ownership.

Tigear-2 reducers share the same footprint and most critical mounting dimensions with original Tigear and many competitive models.

Configuration options

The advanced design concept of the Tigear®-2 reducer product line provides extreme flexibility for applications that require from 100 to more than 6,800 lb.-in of torque. Whether the application requires the compactness of a quill-style input, the durability of a 3-piece coupled input, or a separate keyed input shaft for belt-driven equipment, Tigear-2 is the answer. With four basic reducer configurations that are dimensionally interchangeable with most competitive brands and stock bolt-on accessories, the Tigear-2 reducer line is truly a complete line that is full of value.

Quill input

Space-saving quill-style input reducers for NEMA C-face motors are in both solid and hollow output designs.

Separate input

Separate style input reducers with solid or hollow output shafts are suitable for either belted or direct-coupled motor connections.

3-Piece coupled input

Attaching a stock, 3-piece coupled motor adapter kit to a separate style reducer creates a durable drive package that facilitates easy motor removal and provides protection against shock loads and other unpredictable vibrations.

Tigear-2 sealing system

The totally enclosed, ventless sealing system operates effectively with no pressure vent, no compression chamber. Tigear-2 contains a factory-filled synthetic lubricant that runs cooler, as well as eliminates the need for routine oil changes. All reducers are filled with the proper amount of lubricant for any approved mounting position. Simply install it, then forget it.

Special hydrodynamic wave seal design

The special wave shape (molded into the seal lip) generates a better hydrodynamic film, which is required between the seal and the shaft for long life. This special wave design generates less drag, less heat, and virtually eliminates shaft grooving created by the single-point wear track, which is common with conventional trimmed lip seal designs. The sinusoidal lip of the wave seal effectively pushes external contaminants away and pumps lubricant back into the oil sump.

Special lip construction

Optimized lip-to-shaft contact pressures ensure maximum life. In addition, special sealing elements operate under pressure without detrimental effect on service life or sealing performance.

Factory-filled synthetic lubricant

The standard synthetic lubricant used in Tigear-2 meets H1 food grade requirements and accommodates a wide range of operating temperatures. In extensive laboratory tests, it lowered operating temperatures by 20°F over other popular synthetics. No routine scheduled oil changes are required.

Locking system

The Tigear-2 reducer's Grip Tight tapered bushing system uses concepts that have proven to be effective in the locking mechanism of the Dodge® Grip Tight bearing to simplify installation and removal as well as prevent fretting corrosion problems. There are no loose fasteners to misplace during installation, and the locking nut creates a positive means for easy removal.

Minimum shaft length

The system's tapered bushings allow for mounting in some of the tightest places on almost any size shaft. (Driven shafts need not protrude completely through the reducer bore.)

Bushing options

When used in pairs, the tapered bushings can be used without output keys. Corrosion resistant options are available for severe washdown applications.

SKU: 117869

Awesome transaction

Great company to do business with. Transaction went smooth and quick!

Read moreSKU: 126926

Oem parts

I was repairing a piece of equipment and wanted the same bearings that were removed. MRO Supply had the OEM bearings at a reduced cost. Shipped and received in a timely manner.

Read moreSKU: 117408

P90 coupler

These where a perfect match saved me time and money by getting them fro you guys

Read moreWhen you get to checkout, you’ll be able to select a free gift! Depending on the cart value, you’ll be shown relevant gifts your order qualifies for.

$500

MRO Hat

MRO Golf Balls

MRO Hi-Vis Vests

MRO Mug

$750

32oz Water Bottle

Throw Blanket

30 piece Hex Set

Telescopic Pick Up

$1,250

Golf Cooler

11-in-1 Screw Driver Set

Gorilla Grip Knee Pad

John Deere Oilskin Hat

$2,500

Igloo 1/2 Gallon Jug

Rechargable Headlamp

Larix Trucker Hat

$5,000

Igloo 10 Gallon Cooler

Igloo Party Bucket Cooler

Klein Tools Speaker

Klein Tools 8-in-1

$7,500

GX-6F Pro Golf Range Finder

Bushnell Outdoorsman Speaker

Jaeger 24px Ratcheting Wrench Set

Aspen Beverage Bucket

Item must be unused and undamaged, in it's orginal package. For Dodge there is typically a 10% + $30 US re-stocking fee, although it may vary from case to case. Re-packing fees may apply. Re-stocking fee applies bor both returns for credit and return for exchange.

Warranty is redeemed directly with manufacturer. If your item was damaged during usage, please let us know and we will help you get in touch with your nearest service center, they will guide you about the steps to follow to redeem the manufacturer's warranty.

For further information on our returns/warranty policy, please visit:

https://www.mrosupply.com/page/returnwarranty-policy/