Image for Illustration purposes only. Actual product may vary

$281.33 Each

Prices are subject to change

FREE SHIPPING ON ORDERS OVER $1

Select Quantity

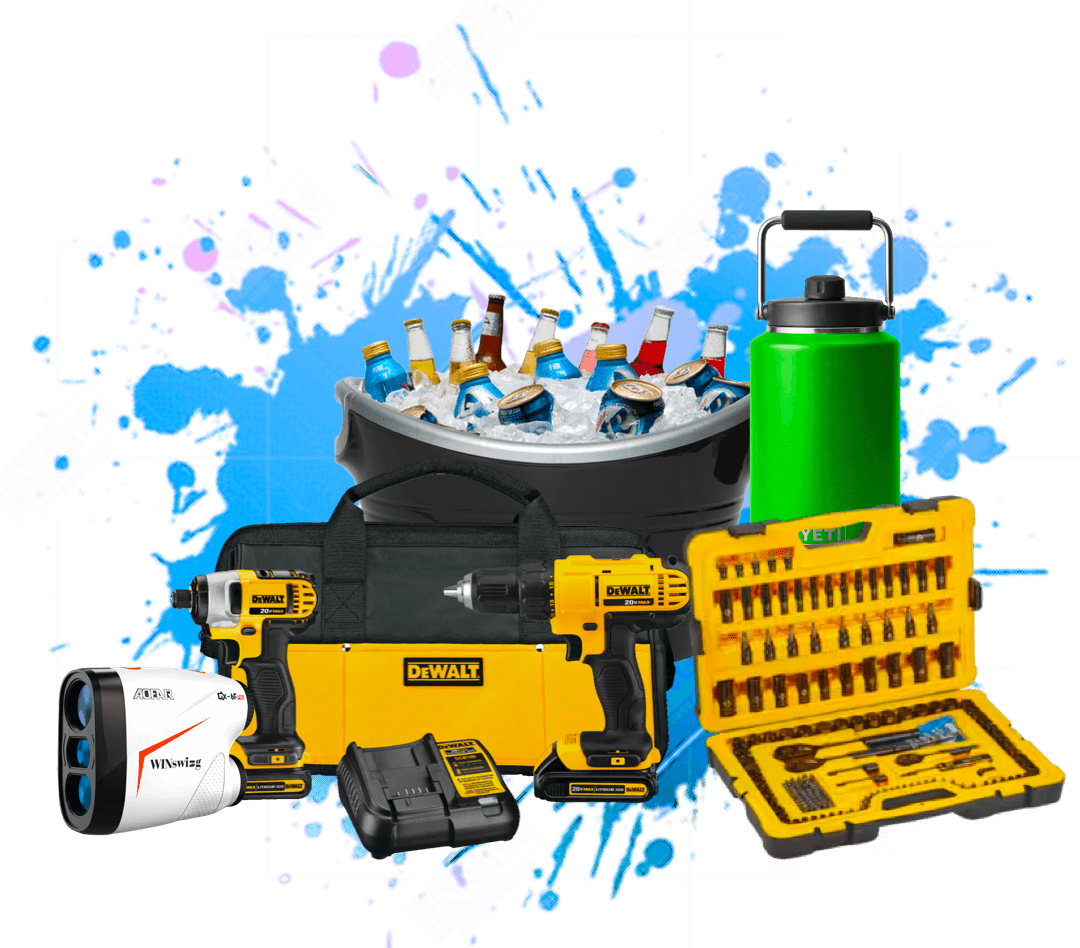

Orders over $500 qualify for a Free Gift

Orders over $500 qualify for a Free Gift

Typically Ships in: 1 day

Returnable: Yes

Flute Type

Spiral

Style

PM-538R

Finish

Bright

Surface Condition

Bright

Series

PM-538R

Length of Cut

6 in

Material

HSS-E (PM)

Shank Type

Straight/Weldon Flat

Shank Diameter

1-1/4 in

Type

Center Cutting Coarse Single End Square End

Cutter Diameter

1-1/2 in

Cutting Direction

Right Hand

Overall Length

8-1/2 in

Tool Size

1-1/2" x 1-1/4" x 6" x 8-1/2"

Number of Flutes

3

Cleveland

PM-Plus

High Performance End MillCharacteristics and Features

- PM Plus; high performance end mills deliver superior performance

- 8% Cobalt substrate

- High vanadium for high red hardness means exceptional toughness and high shock resistance

- Run at higher feeds than conventional HSS or cobalt end mills

- Provide excellent heat and wear resistance

- Freer cutting minimizes heat build-up

- Give excellent finish

- For high volume aluminum roughing

- Multi-flute end mills deliver a smoother finish and are better for peripheral cuts

- Multi-flute end mills have a heavy duty cross section for better rigidity

- Increased number of flutes mean more cutting edges, providing more cutting action

- Coatings reduce heat and abrasion to increase tool life

- The increased lubricity of the coating surface reduces material adhesion and built-up edge, enabling even higher feed rates

- Coatings reduce the amount of torque required for machining to allow more efficient use of equipment

- Increase machining speeds to achieve optimum performance when using

Cleveland

coatings - Applicable on aluminum, non-ferrous materials and copper alloys

When you get to checkout, you’ll be able to select a free gift! Depending on the cart value, you’ll be shown relevant gifts your order qualifies for.

$500

MRO Hat

MRO Golf Balls

MRO Hi-Vis Vests

MRO Mug

$750

32oz Water Bottle

Throw Blanket

30 piece Hex Set

Telescopic Pick Up

$1,250

Golf Cooler

11-in-1 Screw Driver Set

Gorilla Grip Knee Pad

John Deere Oilskin Hat

$2,500

Igloo 1/2 Gallon Jug

Rechargable Headlamp

Larix Trucker Hat

$5,000

Igloo 10 Gallon Cooler

Igloo Party Bucket Cooler

Klein Tools Speaker

Klein Tools 8-in-1

$7,500

GX-6F Pro Golf Range Finder

Bushnell Outdoorsman Speaker

Jaeger 24px Ratcheting Wrench Set

Aspen Beverage Bucket